The 3D printing services at the RSL are out of this world and I’m not just saying that! Recently objects that we printed went up to the international space station. Let’s tell you how it happened.

The Project

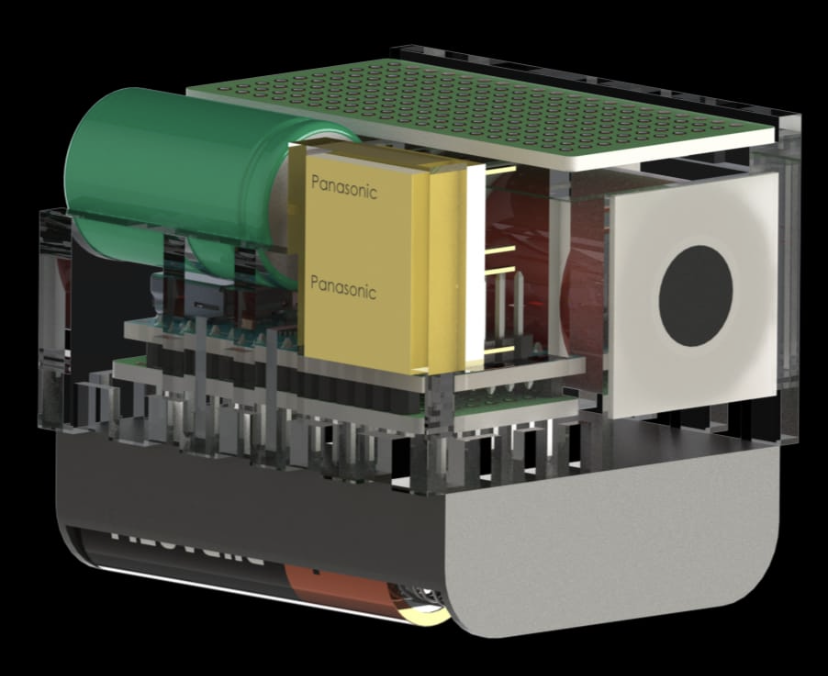

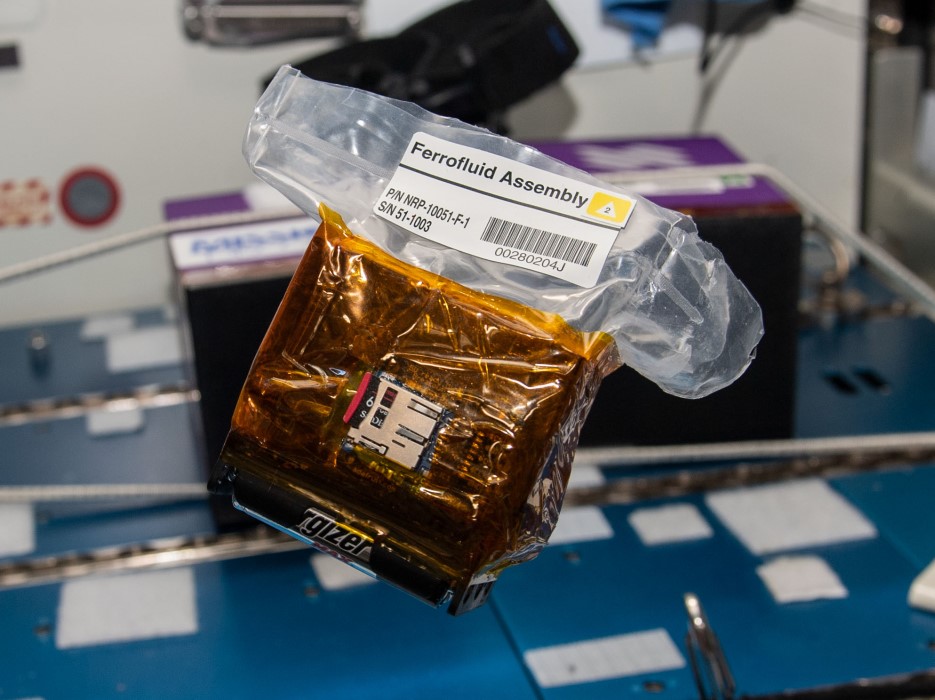

The NG-18 robotic resupply spacecraft launched 7 November 2022, amongst its supplies it brought several experiments to the International Space Station (ISS) including an experiment investigating ferrofluids in microgravity. Ferrofluids are attracted to the poles of a magnet and the experiment’s aim was to investigate how the ferrofluids would act in in negligible gravity. This experiment was assisted by the ISSET-Oxford payload development team, who designed the structure for the experiment, the truss assembly, and the outer cover. This team specialises in developing high school student-proposed research projects for launch to the ISS. The experiment contained a series of electromagnets, which were used to manipulate a ferrofluid sample through a sensing coil.

- Design of the experiment

- The finished experiment at the ISS

The truss, electromagnet coil holders and outer casing were printed by the 3D printing facilities in the RSL. Our New and Emerging Technologies Officer, Richard Smith, discussed the designs with the ISSET-Oxford payload development team and arranged for them to be printed. The structures were printed using Acrylonitrile Butadiene Styrene (ABS) which is NASA safety compliant.

- The design of the printing elements. The green areas are there for support and are removed after printing.

- The final experiment casing and truss parts. You can still see a little of the support structureneeds to be removed.

They were then shipped to NASA Wallops Flight Facility for assembly and launch in November 2022. The assembly was designed in Solidworks and Onshape design software by Dr Daniel Cervenkov, Jack Enright and Dr Mike Foale.

On the ISS, the experiment ran successfully within the 3D printed structure and the results were saved to an SD card. That card returned to Earth on 11 January 2023 as part of the SpaceX CRS-26 Commercial Resupply Service mission along with the results of other experiments.

Find out more about 3D Printing on our guide or by emailing rsl3dprinting@bodleian.ox.ac.uk